|

Diagnostic Connectors, Controller Area Network and Scan Tools

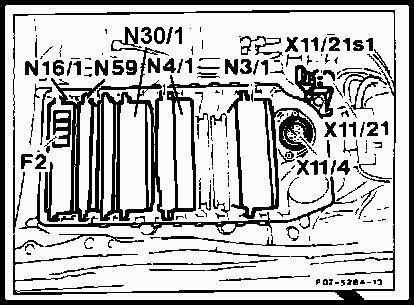

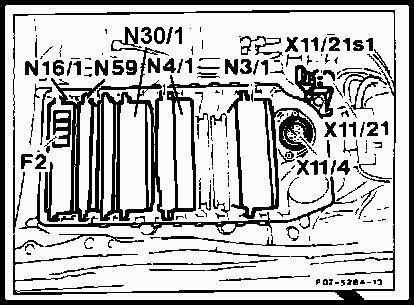

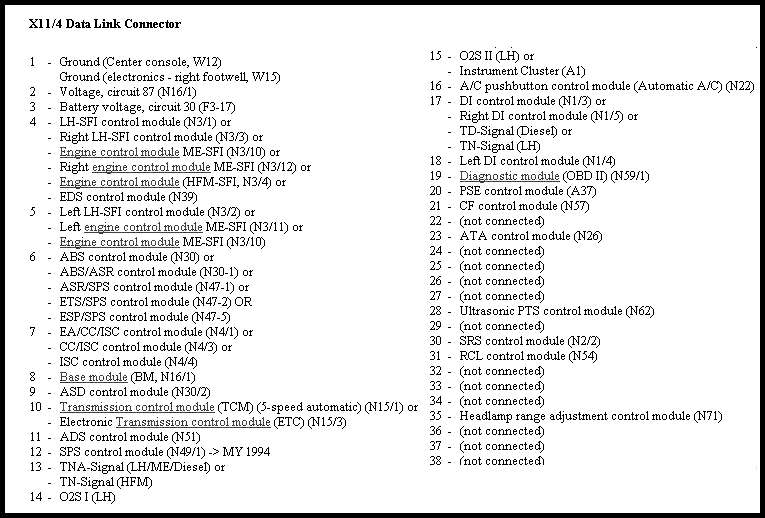

Diagnostic Connectors X11/4 and X11/21

The standard diagnostic test point for all W140 autos is the X11/4, 38 pin connector located in the F23 module box in the

right rear portion of the engine compartment. The module box is closed and air cooled by a blower motor (phased out at end

of '95 model year). The cap which allows access to X11/4 contains a rubber gasket to prevent warm engine air and water

entry. Note the auxiliary Diagnostic X11/21 switch with LED for local DTC readout of the DIAGNOSTIC

MODULE (N59) only.

The standard diagnostic test point for all W140 autos is the X11/4, 38 pin connector located in the F23 module box in the

right rear portion of the engine compartment. The module box is closed and air cooled by a blower motor (phased out at end

of '95 model year). The cap which allows access to X11/4 contains a rubber gasket to prevent warm engine air and water

entry. Note the auxiliary Diagnostic X11/21 switch with LED for local DTC readout of the DIAGNOSTIC

MODULE (N59) only.

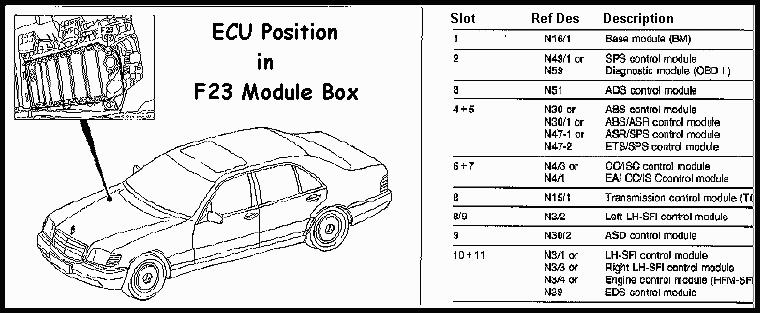

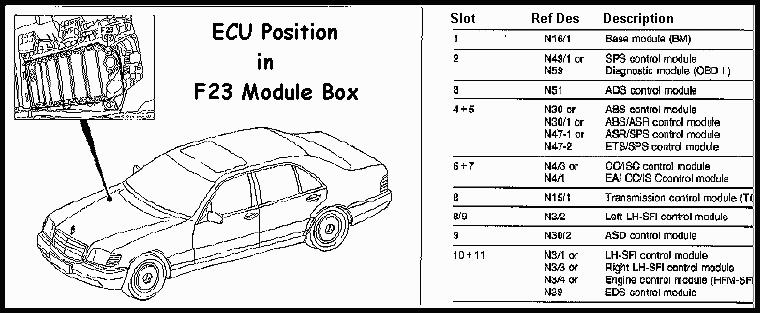

The five (5) ECUs in the F23 box are (California):

N16/1 = Base Module

N59 = Diagnostic Module (California)

N4/1 = Electronic Accelerator/Cruise Control/Idle Speed Control Module

N30/1 = ABS/ASR [AntiLock Brake System/Anti Slip Control] Module

N3/1 = LH-SFI (Sequential Fuel Injection) Module

The picture below shows all possible combinations of ECUs for both California and Federal version vehicles.

Read Stored Codes from X11

Read Stored Codes from X11

To read out DTCs from the Diagnostic Module (N59), locate the X11/21s1 switch as shown in the picture. Remove the protective

snap cap exposing a LED and PUSBUTTON. Turn the IGNITION to ON making sure that all display lamps are illuminated. Press the

PB for apx 5 seconds. If there are no faults in the system, the LED will flash once indicating no faults stored in the system.

Any number of 'flashes' greater than one indicates the DTC stored in the system. Unfortunately, this great user friendly

feature was discontinued at the end of the 1994 model year.

Press the PB again for apx 5 seconds. If there are further faults in the system, the respective DTC will be displayed. If

there no additional faults, the previous DTC will reappear. Repeat this step until the first DTC is displayed. Note all faults

by writing them down.

|

|

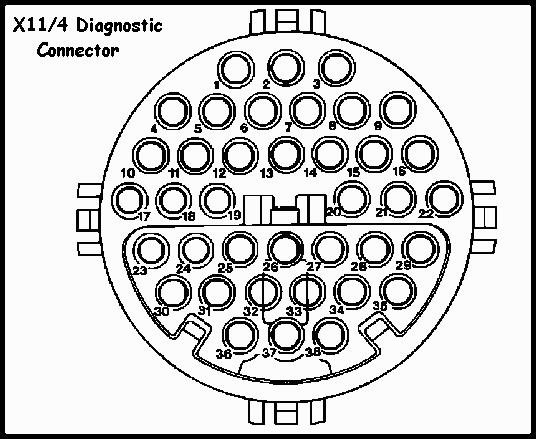

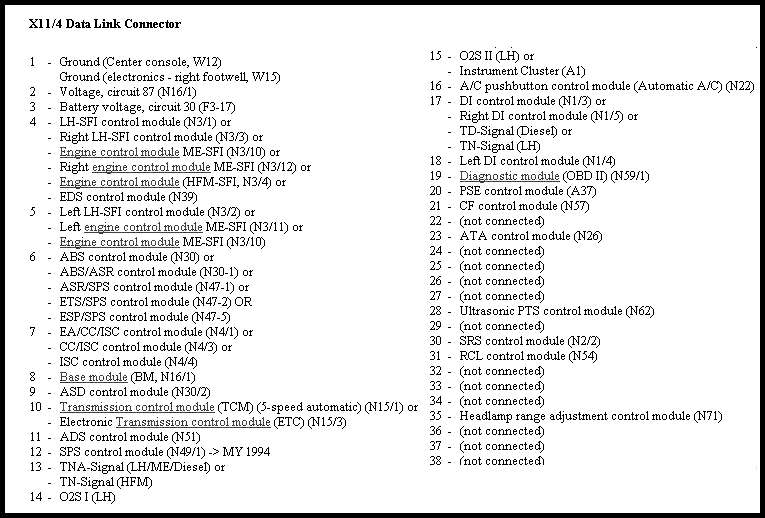

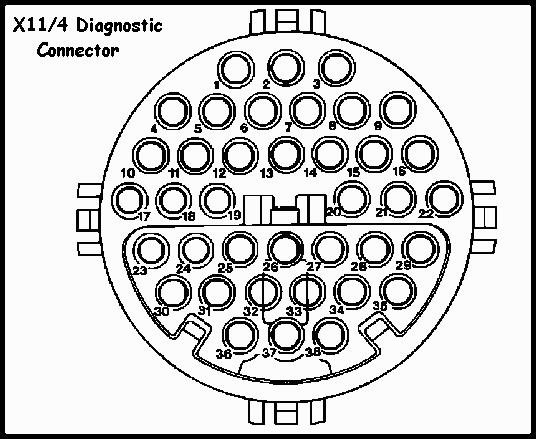

X11/4 Pin Map

ECU Connection Pins of Diag Connector X11/4

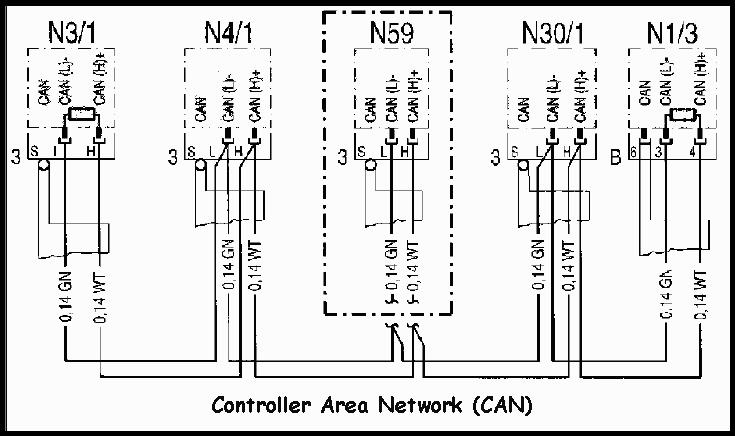

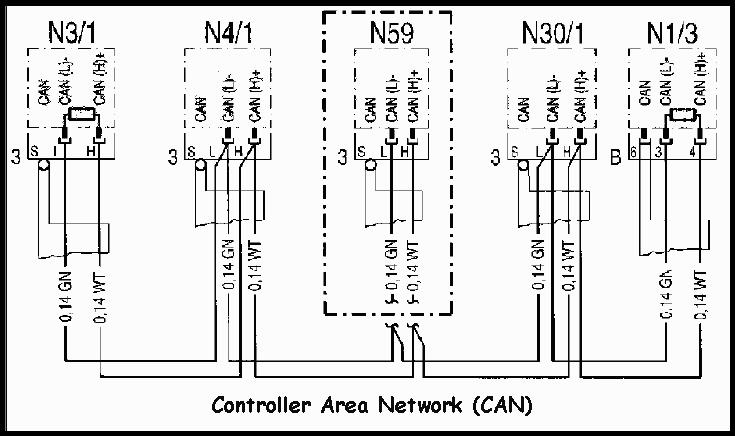

Controller Area Network

The controller area network (CAN) connects all ECUs together electrically so information can be transmitted from one

control module to the others. This exchange network results in more information for the control modules, less wiring and

lower vehicle weight.

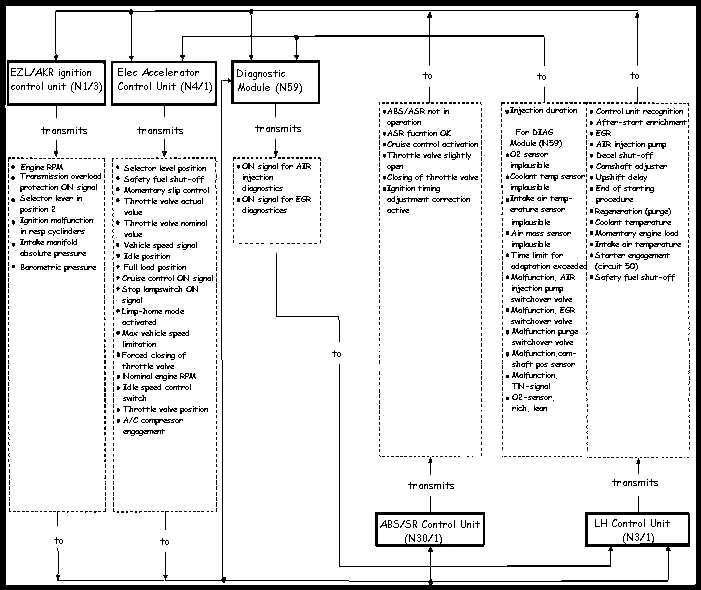

Purpose

The Diagnostic module (N59) monitors the engine control systems and their ECU's to assist the technician during the check/

troubleshooting process. If the module detects a system/component malfunction, it illuminates the 'CHECK ENGINE' light in

the instrument panel.

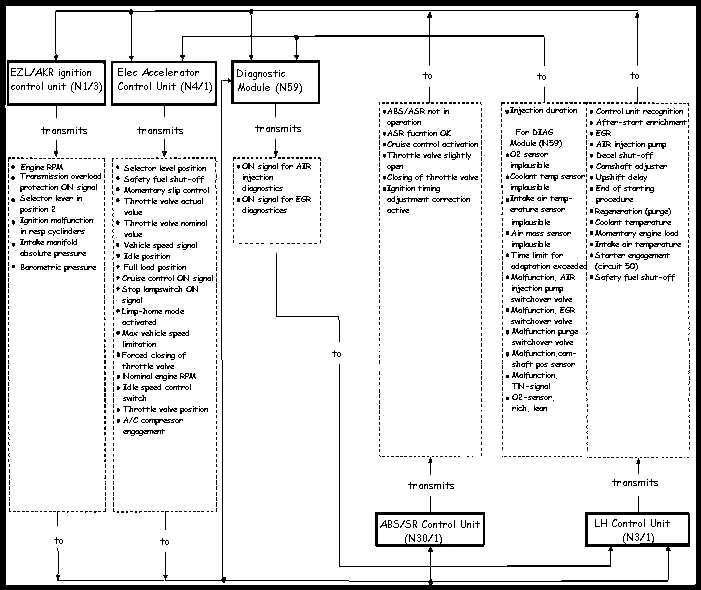

The diagram below shows the interconnection of the five (5) major ECUs (black boxes) and controlling/system monitoring

produced by each module. The CAN bus ties all of the ECUs together. All faults are stored in the DIAG module for

convenience (California cars only.)

DTC Fault Levels

Some ECUs have multiple levels of fault storage. These are called 'Active', 'Registered' and 'Stored'. Here's what they

mean.

Active Faults - These faults are detected while the car is running at idle or speed. They represent a component

that may be or is currently failing. These codes cannot be erased. They are only meaningful with the ignition on and the

engine running so DTCs found in this system with the "key-on-engine-off" usually have no meaning. Sometimes it shows a

components not present on the car as failing so these codes do more to confuse than to serve as a diagnostic tool. But if

the code persists, and the CEL lights, then it indicates a bad component but not necessarily the DTC that's stated!!! Thus

the confustion.

Registered Faults - These faults are recorded in the temporary memory of the of the car's ECUs. This temporary memory

records the the fault indicating that it has occurred and is continuing to occur but it hasn't exceed the preset number of

times to make it a Stored fault. When that certain number of failures has occurred, the fault is now moved to permanent

(Stored) memory and the CEL lights. Some ECUs that have internal fault registers, the CEL may stay on after the Stored or

Permanent fault has been erased if another occurrence of the fault has happened since the 'permanent' fault was stored. To

extinguish the CEL, you should always erase both Stored and Registered faults after fixing the faults indicated.

Stored Faults - These DTCs are sometimes called 'permanent' codes. When that preset number of failures has occurred,

the fault is now moved to permanent (Stored) memory and the CEL lights. These faults are recorded in the ECU's permanent

memory and are the main cause of CEL light. They have been generated because the fault exceeded the preset number of times

set up for for that function. These DTCs can (and should) be erased after the fault is fixed.

Erasing DTC Memory

After eliminating a fault, the respective DTC readout must be cleared as follows: Press the PB for apx 5 seconds and read

out the DTC. Then within 10 secs, press the PB for apx 9 seconds. Then turn the ignition off for 15 secs. Note the EACH DTC

must be cleared INDIVIDUALLY! If the fault has been eliminated and its respective readout erased, the DTC will no longer be

displayed when performing DTC readout.

DTC Readout

To read out DTCs, locate the X11/4 connector near the right rear side of the engine compartment. Remove the protective cover

exposing a 38 pin connector. Plug the mushroom adapter to give access to the 38 pins based on the ECU being tested. Plug in

the three wire leads (Red, Black, Yellow) to the pins referenced for each DTC chart in the Main Menu above. This powers

up the Pointer Scan tool and prepares you to perform the DTC readout.

Now turn the IGNITION to ON making sure that all display lamps are illuminated. Then push the Enter key to cycle the program.

A display of 'No Faults' means the system is clean! Additional faults are displayed by pressing the UP key. All faults

are displayed in plain English on the LCD screen rather than the actual DTC itself. Repeat this step until the first DTC is

displayed. Note all faults by writing them down. After repair of each fault, repeat the above procedure but this time select

'RESET FAULTS' from the menu. Completing this action clears all DTC codes from the selected module's memory.

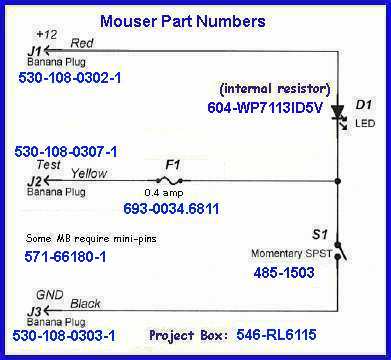

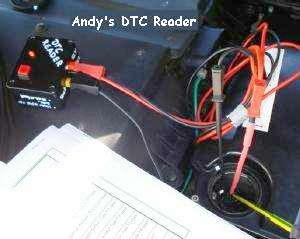

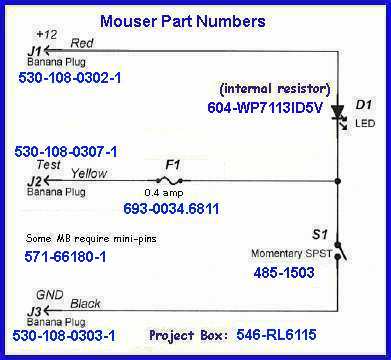

Home Brew DTC Tool

You can build a very handy DTC reader from parts available at Mouser Electronics. This simple tool allows you to read

DTCs from the car without having to spending a large sum of money for a scanner. This tool can be built for under $15. Cost of

all parts detailed below is under $12.00. Parts that are stocked by Mouser are shown in BLUE for

your convenience. Of course you can use a multiplicity of other parts.

You can build a very handy DTC reader from parts available at Mouser Electronics. This simple tool allows you to read

DTCs from the car without having to spending a large sum of money for a scanner. This tool can be built for under $15. Cost of

all parts detailed below is under $12.00. Parts that are stocked by Mouser are shown in BLUE for

your convenience. Of course you can use a multiplicity of other parts.

Click on the links [here] to see the technical specs and pricing for each part.

LED:

Add a 470 ohm-1/4W resistor in series with the + lead if you don't have one with an internal resistor. This one

has an internal resistor -

here

Momentary SW:

Any SPST switch will work but it s/b momentary -

here

Banana Plug:

Any pre-made cable with red, black or yellow plugs can be used. Cut the cable leaving enough to solder to ckt point.

RED -

here

BLACK -

here

YELLOW -

here

Some Mercedes (W140, C140) that have the X11/4 connector require small male pins to plug into the female X11/4 pins. You will need three

(3) pins to replace the banana plugs. Check the pictures below showing two (2) methods of making contact. Personally, I prefer the use of

the male pins shown in the right ['94 SL 500] picture. Mouser stocks pins that are suitable -

here

Fuse:

A low power (less than 1amp) will also work -

here

Box:

Any plastic box will work nicely as long as the parts can fit -

here

The only drawback: You still need a reference document to see what the LED flashes mean. But that can be done, so here's the

schematic of the Code Reader. Note that this unit works for all MBs with ANALOG systems, ie most

cars up to and including 1993. Also some 1994 systems were mixed, both analog and digital.

|

After you build the scan tool, you'll need a DTC Manual to show what the 'blinks' mean!

Click here to show the W140 DTCs for the Diagnostic Module (N59).

Use a Scan Tool

Although not currently being made, the Pointer Scan Tool is an economical alternate designed to recall and reset fault codes

from the your Mercedes-Benz auto. The Fault Code cartridges reads and resets fault stored fault codes. If you can find one on

the used market, you couldn't do better as a DIY code reader tool for your early (pre-OBDII) Mercedes.

Another good scan tool (for pre-OBDII) is the PALM Scanner.

|

Read Stored Codes from X11

Read Stored Codes from X11

The standard diagnostic test point for all W140 autos is the X11/4, 38 pin connector located in the F23 module box in the

right rear portion of the engine compartment. The module box is closed and air cooled by a blower motor (phased out at end

of '95 model year). The cap which allows access to X11/4 contains a rubber gasket to prevent warm engine air and water

entry. Note the auxiliary Diagnostic X11/21 switch with LED for local DTC readout of the DIAGNOSTIC

MODULE (N59) only.

The standard diagnostic test point for all W140 autos is the X11/4, 38 pin connector located in the F23 module box in the

right rear portion of the engine compartment. The module box is closed and air cooled by a blower motor (phased out at end

of '95 model year). The cap which allows access to X11/4 contains a rubber gasket to prevent warm engine air and water

entry. Note the auxiliary Diagnostic X11/21 switch with LED for local DTC readout of the DIAGNOSTIC

MODULE (N59) only.

You can build a very handy DTC reader from parts available at Mouser Electronics. This simple tool allows you to read

DTCs from the car without having to spending a large sum of money for a scanner. This tool can be built for under $15. Cost of

all parts detailed below is under $12.00. Parts that are stocked by Mouser are shown in BLUE for

your convenience. Of course you can use a multiplicity of other parts.

You can build a very handy DTC reader from parts available at Mouser Electronics. This simple tool allows you to read

DTCs from the car without having to spending a large sum of money for a scanner. This tool can be built for under $15. Cost of

all parts detailed below is under $12.00. Parts that are stocked by Mouser are shown in BLUE for

your convenience. Of course you can use a multiplicity of other parts.