|

K6JRF's Page formerly W6FZC My Mercedes Benz S500 Coupe |

|

Analyze and Troubleshoot "Check Engine" MIL and Electronic Control Units (ECU)!

|

Modification of the Viscous Fan Clutch for M119.xxx Engine

Description of Problem

|

|||

Removing the VFC The hardest part of this modification is to get the VFC off the car!

The hardest part of this modification is to get the VFC off the car! For my car, had to remove the protective metal cowling in front that holds the Aux fans so that the fan shroud could be removed. This photo shows how to remove the fan shroud bracket for my S500 cpe. This procedure is valid for any W140 chassis car. All screws are 10mm including the recessed one. The bracket is released by pulling it up and over the hard rubber hood bumpers. |

|||

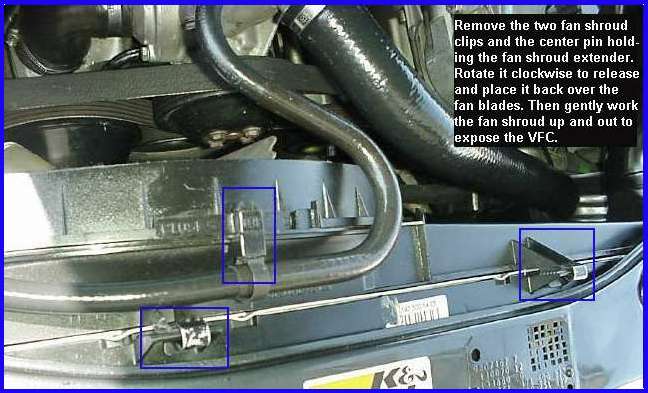

After removing the bracket, remove the fan shroud clips and release the center pin that holds the fan shroud extender. Then

rotate the extender clockwise to release. Place extender back out of the way over the fan blades.

After removing the bracket, remove the fan shroud clips and release the center pin that holds the fan shroud extender. Then

rotate the extender clockwise to release. Place extender back out of the way over the fan blades. Gently pull up and 'wriggle' the fan shroud around the upper radiator hose and place it to the side. Now you can see straight down to the side of the VFC. |

|||

|

VFC Modification This picture shows the modified VFC. The actual modification is quite easy to accomplish. Tools needed include a 3/8" socket with 8mm drive key for the bolt that holds it to the engine. There's not a lot of room to get large tools in front of the radiator, so this part is left up to you.  This modification is courtesy of Stu Ritter, current technical editor of the MBCCA's "The STAR"

periodical, and a former MB shop-owner with 35+ years experience. The following is in his words with some editing for

clarity.

This modification is courtesy of Stu Ritter, current technical editor of the MBCCA's "The STAR"

periodical, and a former MB shop-owner with 35+ years experience. The following is in his words with some editing for

clarity.Take the VFC off the engine. Carefully remove the bms by pushing down on the strip on the open end. The bms will slide out. Drill a small hole on the side that is closest to the clutch (pin) [shown in the inset picture], say 4mm with some overage so as to get a little 4mm bolt with two nuts. There isn't enough thread on that thin strip to trust the threading. Screw the bolt in and double nut it, one on each side of the strip. Bow the bimetallic strip around 1mm to 2mm by adjusting the length of the screw to raise the bms. This will give you full tilt fan engagement right up to the high speed disconnect around 2,500 rpm. You won't believe the amount of fan noise but the engine runs cool as a cucumber. For winter, I reach down with a 4mm wrench, loosen the nuts, turn the bolt 1mm or 2mm to have a normal viscous coupling during the winter when I don't need the added fan noise. jrf notes:It turns out that raising the screw carefully a few mm, causes the vfc to engage when the engine (and radiator) is hot but not when cold. Also it disconnects (if it was engaged) at 2000rpm or so. A very nice feature.  The screw raises the small pin (shown to the right) to fully engage the VFC. Note that complete pin displacement is about

0.070", a little over 1/16". Check the bms picture below to see where to drill: The 'lift' screw hole should be drilled

13/16" in from the end. The large hole on the left is NOT needed. That was done

while doing some experimentation.

The screw raises the small pin (shown to the right) to fully engage the VFC. Note that complete pin displacement is about

0.070", a little over 1/16". Check the bms picture below to see where to drill: The 'lift' screw hole should be drilled

13/16" in from the end. The large hole on the left is NOT needed. That was done

while doing some experimentation. If you wish to 'remove' the mod, remember to NOT put the black plastic cover back. Otherwise you will not be able to turn the screw unless you line it up perfectly with the holes in the cover. This can be done but requires some forethought. But even then space is at a premium so a very small screwdriver is needed. jrf notes:It turns out that raising the screw carefully a few mm, causes the vfc to engage when the engine (and radiator) is hot but not when cold. Also it disconnects (if it was engaged) at 2000rpm or so. A very nice feature. The picture shows a close up of the bms used in the VFC unit. It is the most extensively used general purpose bimetal, TB 1577 A-GE in Europe. These types are used for linearity ranges up to 200 degrees centigrade and useful deflection temperature range up to 350 degrees centigrade. Of course, this range is beyond where it would be useful to keep engine temps within a safe, reliable range.

Future Plans |

|

Send me |

But the kicker is that the VFC doesn't engage until the temperature is into the RED region on the

temperature gauge! Much too late! So this modification changes the clutch to lock up at all times. It's very simple to do

and adds greatly to the cooling of the engine.

But the kicker is that the VFC doesn't engage until the temperature is into the RED region on the

temperature gauge! Much too late! So this modification changes the clutch to lock up at all times. It's very simple to do

and adds greatly to the cooling of the engine. When two metals with dissimilar thermal expansion coefficients are bonded together, they produce useful devices for detecting

temperature changes. A typical pair of brass and steel with expansion coefficients of 19 and 13 ppm per degree C respectively

are commonly used. As heat is applied, the bms bends away from the metal with the greater

expansion. In this case, brass.

When two metals with dissimilar thermal expansion coefficients are bonded together, they produce useful devices for detecting

temperature changes. A typical pair of brass and steel with expansion coefficients of 19 and 13 ppm per degree C respectively

are commonly used. As heat is applied, the bms bends away from the metal with the greater

expansion. In this case, brass.