|

K6JRF's Page formerly W6FZC My Mercedes Benz S500 Coupe |

|

Analyze and Troubleshoot "Check Engine" MIL and Electronic Control Units (ECU)!

|

MAF Contamination & Lambda

Description

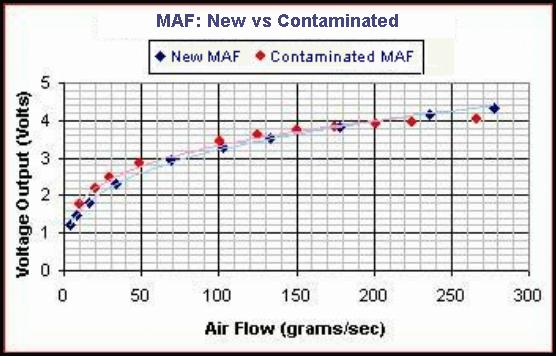

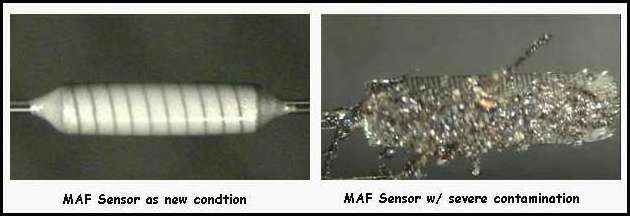

To double-check the readings I got with the AST Retreiver, I hooked up my Lambda Tester (M0039) and verified the 70% Lambda value but couldn't measure the MAF volume since it doesn't have the capability. So now, it's time to see if I can fix it. Fixing The Problem. . . To confirm this disconnect the MAF sensor connector. It's located on the drivers side and takes a quarter turn to loosen it. With the car running, using a Lambda tester or equivalent, this should force the car into the learned AZ/EL precoded fuel management mode and drop to 50% area. In this mode, airflow is generated by using rpm and throttle position instead of reading the MAF sensor. If the lean drivability symptoms go away, the MAF sensor is probably contaminated. If the lean drivability symptoms do not go away the MAF sensor is probably not contaminated and it might well be the O2 sensor. Mercedes says that you should replace the MAF since it cannot be repaired. With the cost of about $250, it's a fairly large repair bill. This problem can be fixed and it can be done by just about everybody. Put it this way, what do you have to lose to try this method?? Not much, just a few dollars for the cleaner. When you look at the MAF what you see with their naked eye is very little. It is nearly impossible to determine if a MAF sensor's thermistor is dirty or clean from looking at it without magnification and good lighting. When viewed under a microscope, this is what you might see.

An alternate cleaner is a non-chlorinated brake cleaner that leaves no residue. I found a cleaner that carries the Auto-Zone

brand that is guaranteed to leave no residue. Don't use carburetor cleaner b/c it will leave a chemical residue.

An alternate cleaner is a non-chlorinated brake cleaner that leaves no residue. I found a cleaner that carries the Auto-Zone

brand that is guaranteed to leave no residue. Don't use carburetor cleaner b/c it will leave a chemical residue.Disconnect the NEGATIVE battery cable and remove the MAF from the car. Spray the inside of the MAF with the sensor cleaner thoroughly being careful to clean the sides as well. Be careful to spray the center wire since it's very thin and if it breaks, you will have to replace the MAF. Clean it well and let it air dry for 20 to 30 minutes. You can use compressed air to remove any remaining particles but make sure you bleed the pressure down to 70 psi so as to not break the wire. When it's dry put it back into the vehicle and reconnect the NEGATIVE battery cable. You will need to drive the vehicle several miles to let the fuel computer "relearn" your specific driving condition but it will adjust quickly since the MAF is now properly sensing the air flow. The fuel computer will have to readjust over a longer term but that will happen; it just takes some driving time. Of course you could reset the fuel computer to 'nominal' values using the scanner. While putting the car back together, I noticed that the IAT sensor (B17/7) was also heavily contaminated. So it was cleaned and appeared perfect after the cleaning. Results. . . After cleaning the MAF and IAT, Lambda tests were back at "50%" point (as measured on the M0039) at both idle and 2500rpm; see MENU#4 for Lambda test methods. This morning (3/27), I measured the same parameters using the AST Retreiver. Air mass measured 23.2 Kgm/h, an increase of apx 25+% which shows that the MAF was contaminated! The scanner also confirmed the M0039 ON/OFF ratio 50% oscillating measurements as correct. So, the experiment was a success! To say I'm pleased is an understatement! This a worthwhile procedure which may just save you the cost of a MAF or an IAT or both! Comments. . . This section was written after reading the number of threads concerning the effectiveness various filters and MAF contamination. The information provided puts a finishing touch on my observations. The 'real-world-test' described in this link is the best that I've seen and shows test results of using paper, foam and cotton composition air filters in a real auto, '92 Miata, driven on real roads in the Pacific Northwest for 500 miles for each filter. Be sure to read the FLOW and FILTRATION tests. Their conclusions say it all; must reading! The second is a combination link showing all the recent discussions on K&N and paper filters. Also good reading. * The AST Retreiver's standard measurement units for Air Mass is "kilo grams/hour", abbreviated as "Kgm/h". ** I use K&N filters in my car and they claim that their filter oil does not 'fly-off' even in high air flows and it can NOT contaminate an MAF. Referencing K&N's installation sheet under "Performance Hints", K&N says "Caution: Extreme fine dust, agriculture or off-road use, will pull the oil from the element. Frequent re-oiling of the element's clean side may be required". For more info, click here to see K&N Tests. |

|

Send me |